Regular maintenance is essential for you as a technician because it boosts your equipment’s longevity and efficiency. By conducting routine checks, you can spot small issues before they turn into costly problems, allowing you to focus on your tasks without unexpected interruptions. This proactive approach not only enhances safety but also leads to career advancement opportunities. It also demonstrates your commitment to quality work. Plus, maintaining your tools and understanding specific vehicle needs keeps your skills sharp. Remember, embracing maintenance now can save you time and money later, and there’s always more to explore about optimizing your maintenance strategies.

Key Takeaways

-

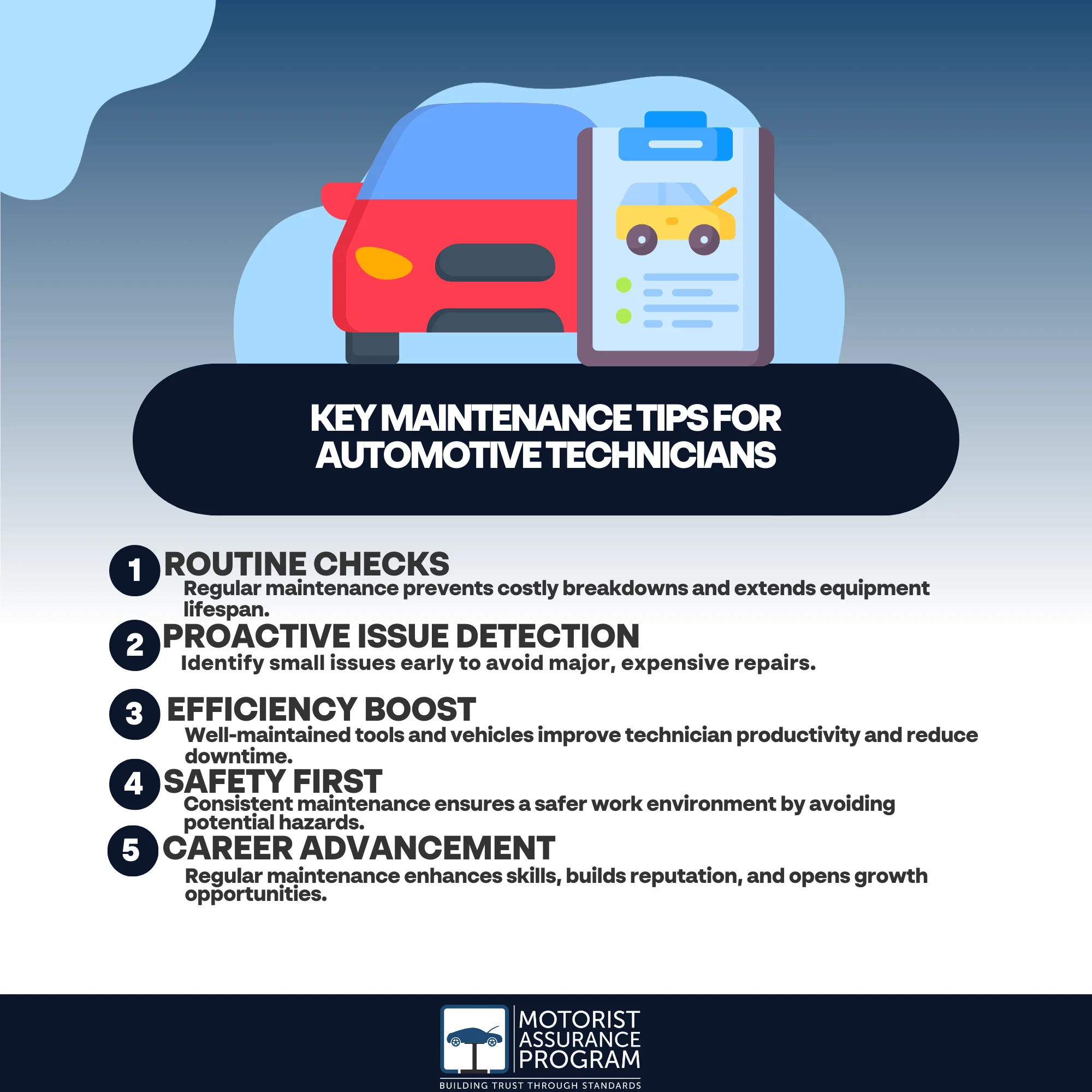

Regular maintenance enhances equipment longevity and efficiency, preventing costly breakdowns and repairs.

-

Proactive maintenance strategies identify minor issues early, helping avoid major problems and ensuring safety.

-

Well-maintained tools and equipment increase technician efficiency, reducing downtime and enabling focus on tasks.

-

Consistent maintenance practices support career advancement opportunities and professional development for technicians.

-

Effective scheduling of maintenance tasks helps optimize workflow, accountability, and customer satisfaction.

Importance of Regular Maintenance

Regular maintenance isn’t just a recommendation; it’s a necessity for keeping your equipment running smoothly. When you engage in regular upkeep, you’re investing in the longevity and efficiency of your tools.

Implementing preventive strategies can help you identify minor issues before they escalate into major problems, such as those related to fluid checks and engine maintenance. Think of it as a safety net that can save you time and money in the long run.

To achieve peak performance, you need to establish a consistent maintenance frequency. This guarantees that every component of your equipment is checked and serviced at the right intervals.

Whether it’s lubricating moving parts, checking for wear and tear, or replacing filters, staying proactive is key.

Key Benefits for Technicians

By prioritizing maintenance, technicians release a range of key benefits that enhance both their productivity and the reliability of their equipment.

Regular maintenance not only keeps tools in top shape but also sharpens your technical expertise, allowing you to tackle challenges more effectively. When equipment runs smoothly, you can focus on your tasks without unnecessary interruptions.

Conducting regular vehicle inspections guarantees that potential mechanical issues are identified before they lead to more significant problems. This proactive approach directly contributes to a safer work environment.

Here are some key benefits you’ll experience:

-

Increased Efficiency: Well-maintained equipment operates at peak performance, reducing the time you spend on repairs and downtime.

-

Enhanced Safety: Regular checks help identify potential hazards, guaranteeing a safer work environment for you and your colleagues.

-

Career Advancement: By showcasing your commitment to maintenance, you position yourself as a dependable technician, opening up opportunities for promotions and growth.

Essential Tools for Maintenance

To maintain that high level of efficiency and reliability, having the right tools at your disposal is fundamental. Your tool selection can make a significant difference in how effectively you perform maintenance tasks.

Start by evaluating your maintenance inventory to guarantee you have the basics: wrenches, screwdrivers, pliers, and a reliable torque wrench. Each tool plays a vital role in different maintenance scenarios, so knowing their specific functions helps you tackle various issues confidently.

Understanding the unique maintenance needs of electric and hybrid vehicles, such as high-voltage battery considerations, is imperative for technicians looking to stay ahead in the industry. Consider exploring charging infrastructure and resources to better grasp the specifics of EV servicing.

Consider investing in diagnostic tools as well. Scanners, multimeters, and pressure gauges can provide critical insights into a vehicle’s performance, allowing you to identify problems before they escalate.

Keep your tools organized and in good condition; a cluttered workspace can lead to mistakes that cost both time and money.

Additionally, don’t overlook safety equipment like gloves and goggles. They’re just as important as your tools, making sure you stay safe while you work.

Inspection Techniques for Vehicles

A thorough inspection is essential for ensuring vehicle safety and performance. By implementing effective inspection techniques, you can identify issues before they become major problems.

Here are some key methods to enhance your inspection process:

-

Visual Assessments: Regularly check for wear indicators, leaks, and any unusual signs on the vehicle’s exterior and under the hood.

-

Fluid Analysis: Analyze engine, transmission, and brake fluids to detect contamination or degradation, which can signal underlying issues.

-

Electronic Inspections: Utilize advanced diagnostics techniques and system checks to evaluate the vehicle’s electronic components, ensuring everything functions as intended.

Common Maintenance Tasks

When it comes to keeping vehicles in top shape, you can’t overlook common maintenance tasks.

Regularly checking equipment calibration, following inspection checklists, and ensuring safety protocol compliance are essential steps you should take.

Equipment Calibration Procedures

Regular calibration of equipment is vital to guarantee accuracy and reliability in your tasks. By implementing effective calibration techniques, you can enhance equipment accuracy, making certain that your work meets the highest standards.

Regular calibration extends the life of your tools and prevents costly mistakes that may arise from faulty measurements.

To achieve ideal results, consider these key practices:

-

Schedule Calibration: Set a routine to calibrate your equipment based on usage frequency and manufacturer recommendations.

-

Document Results: Keep a log of all calibration activities and results. This helps track performance trends and identify when adjustments are needed.

-

Train Personnel: Make certain that everyone using the equipment is trained in calibration procedures. This fosters a culture of accountability and precision.

Routine Inspection Checklists

Routine inspections are crucial for maintaining equipment performance and preventing unexpected downtime. By conducting regular routine checks, you can identify potential issues before they escalate into costly repairs.

A well-structured inspection checklist is your best ally in this process. It helps you stay organized and guarantees you cover all critical components during your evaluations.

When creating your checklist, consider including maintenance tasks like checking fluid levels, inspecting belts and hoses, and reviewing tire conditions.

Make sure to establish an appropriate inspection frequency that aligns with your equipment’s usage and manufacturer recommendations. For instance, some machinery might require weekly checks, while others could be serviced monthly or quarterly.

Safety Protocol Compliance

Guaranteeing compliance with safety protocols during maintenance tasks is vital for protecting both personnel and equipment.

By adhering to these standards, you reduce the risk of accidents and equipment failures, leading to a safer workplace. Regular safety audits and risk assessments help identify potential hazards and guarantee that you’re following the necessary guidelines.

Here are a few key practices to keep in mind:

-

Wear appropriate personal protective equipment (PPE): Always use gloves, goggles, and other safety gear as required.

-

Follow lockout/tagout procedures: This prevents accidental machine start-up during maintenance, safeguarding you and your coworkers.

-

Document safety checks and maintenance records: Keeping detailed records helps in future risk assessments and guarantees accountability.

Maintenance Scheduling Best Practices

Effective maintenance scheduling is important for minimizing downtime and maximizing efficiency in any technical environment. By establishing a clear maintenance frequency, you can guarantee that tasks are performed regularly, reducing the risk of unexpected failures.

Utilizing scheduling software simplifies this process, allowing you to implement preventive strategies that keep equipment in top shape.

Technician accountability is essential; each team member should know their responsibilities and deadlines. This clarity cultivates a culture of ownership and encourages proactive maintenance.

Consider workflow optimization when planning tasks—organizing jobs in a logical sequence can save time and resources.

Good time management is essential, as it helps you allocate resources effectively while maintaining performance tracking to monitor progress.

Adjust schedules based on data and feedback, improving future maintenance efforts.

Don’t underestimate the importance of customer communication; keeping clients informed about scheduled maintenance builds trust and satisfaction.

Lastly, maintain thorough maintenance documentation. This record not only helps in tracking past performance but also serves as a reference for future planning.

Training and Skill Development

Training and skill development are key components of a successful maintenance program. As a technician, investing in your growth not only enhances your expertise but also guarantees you provide exceptional service.

Engaging in various educational opportunities strengthens your skills and keeps you motivated.

Consider incorporating these avenues into your training plan:

-

Hands-on workshops: These provide invaluable practical experience, allowing you to apply theories to real-world scenarios. You gain confidence while tackling complex issues with guidance from experienced professionals.

-

Online courses: With flexible schedules, these courses offer a wealth of knowledge at your fingertips. You can learn at your own pace, covering topics from basic maintenance to advanced diagnostics.

-

Networking events: Connecting with other technicians can expose you to new techniques and best practices. Sharing experiences helps you grow while building a supportive community.

Staying Updated on Regulations

Staying updated on regulations is essential for your success as a technician.

When you keep track of industry standards and adapt to legal changes, you not only guarantee compliance but also enhance your credibility.

Here are some key areas to focus on:

-

Training Programs: Participate in ongoing training opportunities to stay ahead of the curve.

-

Documentation: Keep meticulous records of your work, ascertaining that they align with industry standards.

-

Networking: Connect with peers in your field to share insights and updates on best practices.

Adapting to Legal Changes

Steering through the ever-changing landscape of regulations is essential for technicians who want to maintain compliance and avoid legal pitfalls. Staying informed about legal updates is vital, as these changes can impact your daily operations and the services you provide.

Participating in regulatory training is a proactive way to guarantee you understand any recent changes and how they affect your work. These training programs help you grasp the nuances of compliance, allowing you to adapt your practices accordingly.

Establish a routine for reviewing regulatory updates regularly. This could mean subscribing to industry newsletters, participating in forums, or joining professional organizations that provide valuable resources.

Frequently Asked Questions

How Can Technicians Track Their Maintenance Tasks Effectively?

To track your maintenance tasks effectively, use task management software to streamline maintenance scheduling. Set reminders, prioritize tasks, and keep detailed records to guarantee nothing gets overlooked and you stay organized throughout your workflow.

What Are the Most Common Mistakes Technicians Make During Maintenance?

You might think skipping maintenance frequency won’t hurt, but neglecting checks can lead to bigger issues. Relying solely on basic troubleshooting techniques often results in overlooked problems, costing you time and resources down the line.

How Does Maintenance Affect Technician Job Satisfaction?

Maintenance greatly impacts your job satisfaction. When you cultivate a strong maintenance culture, you enhance your sense of job fulfillment. You’ll feel more accomplished and valued, leading to increased motivation and overall happiness in your work.

Are There Certifications for Technicians Specializing in Vehicle Maintenance?

Yes, there are certification programs for technicians specializing in vehicle maintenance. These programs help you meet industry maintenance standards, enhance your skills, and boost your credibility, ensuring you’re well-prepared for the demands of the job.

What Role Does Technology Play in Modern Maintenance Practices?

Technology revolutionizes modern maintenance practices. You leverage predictive analytics and maintenance software to anticipate issues before they occur, streamline operations, and enhance efficiency. This proactive approach saves time and reduces costs, ensuring ideal vehicle performance.

Conclusion

By prioritizing maintenance, you not only enhance your skills as a service technician, but also boost vehicle longevity, ensuring smoother rides for your customers. Remember, a well-maintained vehicle is like a well-trained performer—ready to wow the audience. So, equip yourself with the right tools and knowledge, and watch as your reputation flourishes, building lasting trust and loyalty with every tune-up you perform.